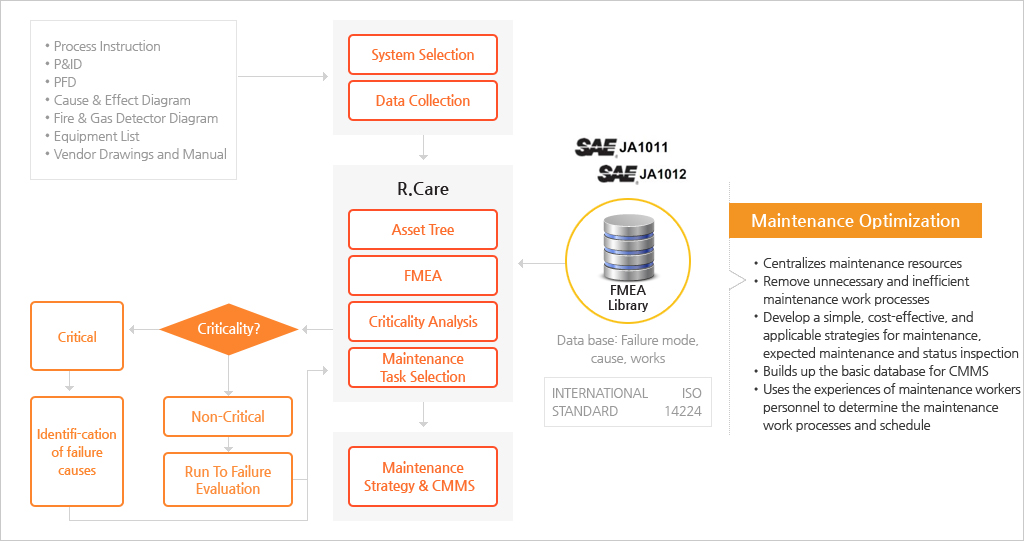

R.Care is an RCM analysis solution that supports the ability to determine possible failure modes and causes. R.Care helps to select the optimal regular equipment maintenance and preventive maintenance strategies. Optimal strategies are derived using a detailed analysis of specific equipment maintenance characteristics of large plants, such as refineries, petrochemical plants and power plants. The equipment is also analyzed on the basis of the characteristics of the operating environment and functional criticality to ensure equipment functionality is maintained efficiently, economically and effectively.

Key Functions

| Asset Tree |

|---|

|

| Failure Modes & Effects Analysis (FMEA) |

|---|

|

‘FMEA Library’ is used to manage failure modes and failure effects of equipment. |

| Criticality Analysis |

|---|

|

| Maintenance Task Selection |

|---|

|

Preventive maintenance work processes, maintenance cycle periods, responsible department assignment, and duration are managed using FMEA |

To prepare for a successful R.Care implementation, RCM consulting should be performed first.