Overview

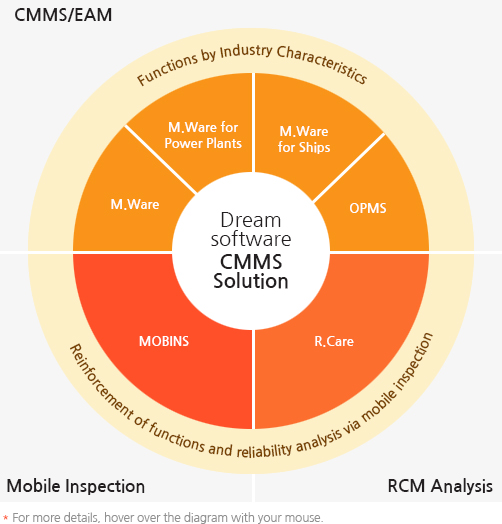

Our maintenance management solution is designed to reflect all the key functionality essential for maintenance work process management. We utilize best practices accumulated from a variety of industries such as general manufacturing, power generation, shipbuilding, and automobile manufacturing to provide our customers the most effective maintenance management system.

CMMS/EAM

M.Ware for Ships

M.Ware for Ships is a maintenance management solution for ships. It helps to establish optimized maintenance and inspection plans by analyzing the condition of equipment on the basis of functions unique to ships maintenance. For example, managing the hull, tools, and other equipment aboard ships and off-shore plants.

CMMS/EAM

OPMS

Optimized Power Plant Management System (OPMS) is an integrated plant management solution that modularizes and integrates key functions for the operation of Independent Power Producers (IPPs) and other middle and small sized plants. This web-based software provides a complete standardized plant operation management solution for plant maintenance. The single system provides additional features to help with functions such as human resources, payroll, finance and accounting.

RCM Analysis

R.Care

R.Care is a Reliability Centered Maintenance (RCM) solution that analyzes failure modes, causes, and failure effects of plant equipment from the perspective of safety, operability, and economy and assesses results to propose optimized preventive maintenance strategies.

Mobile Inspection

MOBINS

MOBINS is a mobile inspection management solution that enables preventive inspection and spare parts management by transmitting a preventive inspection plan in a computerized maintenance management system (CMMS) to mobile equipment and recognizing barcodes and QR codes of equipment while onsite.

CMMS/EAM

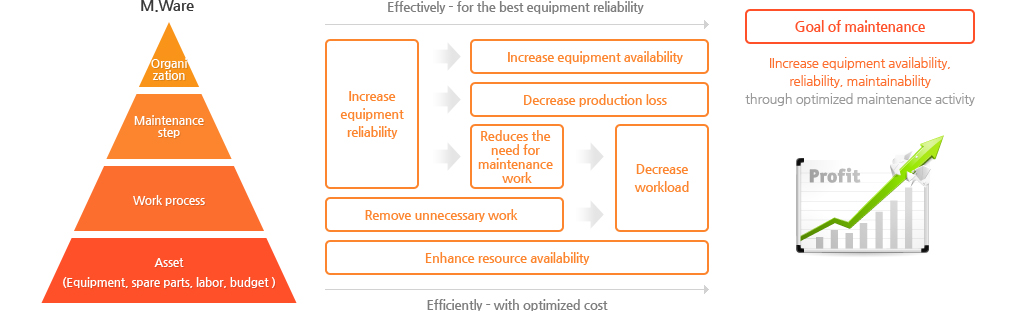

M.Ware

M.Ware is a sophisticated maintenance management solution that establishes an optimized scheduled maintenance program and enables efficient spare parts purchases and management. It uses an equipment master database for work management, preventive maintenance, inspection, spare parts management, and KPIs. Its design considers the characteristics of each customer’s specific maintenance work processes.

CMMS/EAM

M.Ware for Power Plants

M.Ware for Power Plants is a maintenance management solution for power plants. It establishes optimized maintenance and inspection plans by analyzing the condition of plant equipment on the basis of functions unique to power plant maintenance. For example, electricity generation record, outage management, project management (overhaul), and safety management (red tag).

Features

Web-based operating environment

Accessible anywhere, anytime with internet access (via Internet Explorer™, Google Chrome™, Mozilla Firefox®, and more.)

Collaboration-oriented functional design

- Establishes an optimal facility management system by summarizing the relationship between the customer's actual maintenance work process and each management task.

- Provides essential functions for equipment management such as equipment master, preventive maintenance and inspection, material management, and maintenance index (KPI)

Function designs are work site centered

- An optimized CMMS utilizes an organized association of the customers actual maintenance work process and individual management activities.

- To perform the requiredmaintenance management functions it provides features, such as equipment and spare parts master database, preventive maintenance and inspection, and key performance indicators (KPIs).

Reasonable setup cost and customizable

- Provides optimal computerized maintenance management solution that reflects client's budget, equipment scale and characteristics, and unique maintenance processes.

- Functional configuration according to customer's needs (minimum to maximum configuration levels)

User-friendly user interface(UI)

Provides a UI that suits your business environment, including simple data entry, user filter searches, equipment hierarchy search, various reports, quick menus and favorites list.

Interface with diverse infrastructure systems

- Provides a seamless interface with a diverse variety of enterprise resource planning (ERP) systems including Oracle and SAP.

- Interfaces with a mobile inspection system and electronic document management system (EDMS).

- Supports an interface API with PIS, CMS and EMS.

Expected effects

- Increase of overall equipment effectiveness (OEE)

-

효과

Manages the failure mode, cause and action history.

- Minimizes failure time and downtime.

- Reduces temporary shut downs, productivity loss, damage, and defects.

- Enhanced equipment visualization

-

효과

Provides maintenance key performance indicators

KPIs.Provides the ability to view the status of equipment and assets at a glance.

- Improves equipment reliability

-

효과

Work order centered, condition based maintenance in accordance with time-based maintenance (TBM) and usage-based maintenance (UBM).

- Increases reliability of equipment through condition-based maintenance.

- Minimizes unscheduled maintenance costs and productivity losses due to unexpected accidents and shutdowns.

- Enhances work quality

-

- Accumulates and shares maintenance-related technologies.

- Standardizes work methods, labor and spare parts information.

Enhances work quality by sharing technical expertise, personal experiences and standard procedures knowledge among maintenance staff.

- Ensures accurate spare

parts management -

효과

Links work order, equipment and spare parts information.

- Maintains accurate inventory levels.

- Reduces unnecessary purchases of spare parts.

- Improves equipment return on investment (ROI)

-

효과

Supports the use of condition-based preventive

maintenance.- Improves the ROI of equipment by reducing maintenance costs and using improved equipment, spare parts and maintenance procedures.

- Minimizes unscheduled maintenance

- Increases efficiency and

database validity -

- Enhances ease of use and access.

- Accumulates maintenance data systematically using logical and continuous methods.

- Increases the efficiency of maintenance using KPIs.

- Ensures database validity.

- Optimizes onsite

work activities -

효과

Expedites the inspection of onsite equipment and spare parts using smart mobile devices.

Optimizes onsite work activities based on data collected during onsite inspections.