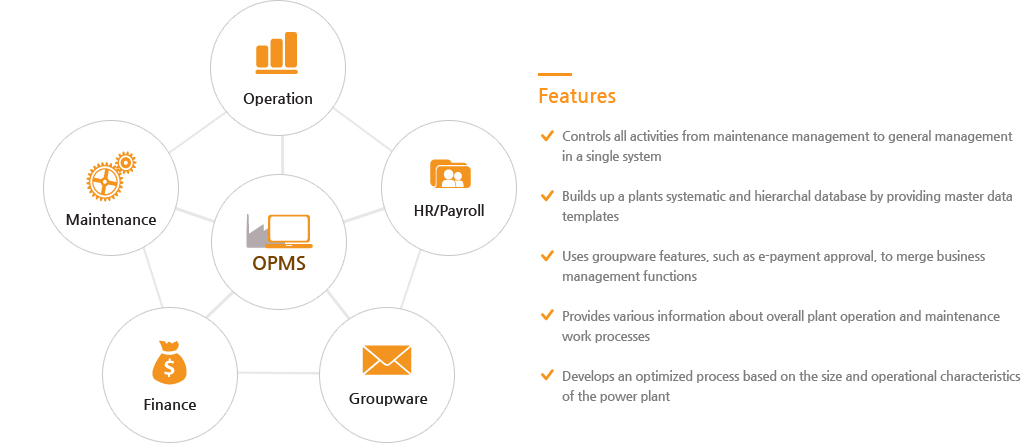

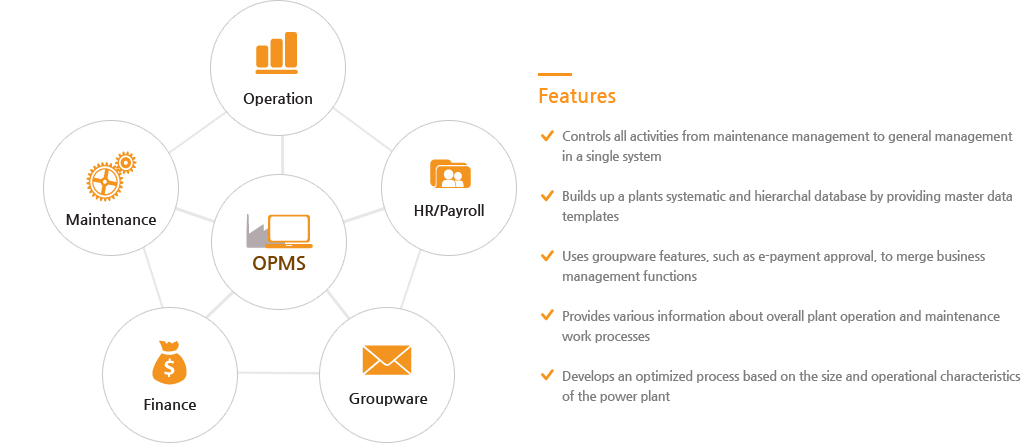

Optimized Power Plant Management System (OPMS) is a solution that integrates the key management functions of mid- and small-size independent power plants (IPPs). It integrates maintenance, operations and general management (finance, human resources, payroll, and groupware).

Key Functions

주요기능

| Operation |

Provides equipment operations information to the plant operator in a timely manner. |

- Development of operational information

- Shut down and failure information

- Equipment failure status and statistics

- Operational handovers

|

| Maintenance |

Supports and optimizes maintenance work performance using a system design that reflects the unique characteristics of a power plant’s equipment. |

- Equipment master management

- Work management

- Preventive maintenance and inspection management

- Red Tag (Safety)

- Spare parts management

- Maintenance activities analysis using key performance indicators (KPIs)

|

| Finance |

- Makes work easier and increases efficiency by automating the accounting and finance management processes

- Reveals system improvements, including tax management, pursuant to local tax laws

|

- Accounting journal and asset management

- Taxation and budget management

|

| HR/Payroll |

Increases efficiency using an automated HR and payroll management system

Exposes employee time and attendance records and helps manage salaries to fit a local environment |

- HR and time/attendance management

- Payroll/Account management

|

| Groupware |

Promotes seamless communication and information sharing among and between employees using groupware

Supports quick decision making through e-approval |

- Business management/Knowledge sharing

- Community/Messenger

|

Case

- Implementation of OPMS for a power plant for Al-Qatrana, Jordan

- Implementation of OPMS for a diesel power plant for Al-Manakher, Jordan

R&D

- Development of a standard asset and equipment management system for O&M business (Research project, KOSPO)